Products

The market’s fastest, strongest and most durable new SATEC system.

SATEC: Continuous Thermal and Acoustic Insulation System

What is Green Wall Panel System?

Green Wall is a constructive panel, coposed of a fireproof EPS block (from 4” a 8”) and metal studs (20 gauge to 18 gauge) with an impact capacity of 128 pound x inches 2. (See technical sheet) This panel can be given the finish you prefer, with a basecoat, mesh and paints, simulating stone, block, brick, wood, polished, etc. This product is thermoacoustic, increasing considerably the thermal and acoustic comfort of interior spaces.

Certificate*: Test approved Hurricane 5 Seismic Class C, D and E.

*Miami Dade County

Break free from traditional systems with Green Wall Panel System

Times change and so do the needs of projects. That’s why we show you the solution to adapt your project to the new trends of efficient, fast and durable golbal construction.

Benefits

of Green Wall

The Green Wall system offers several benefits that make it a superior option compared to traditional methods such as the use of concrete or sheet rock.

Fast

Installation of the Green Wall system is fast, as the EPS panels are efectively placed and covered with the final cladding in a short time, significantly shortening construction times compared to concrete and rock board, which require more phases and drying time.

Clean

It is a clean process, as most of the work is done on the outside of the building. This minimizes the generation of debris and waste compared to concrete, which involves mixing, pouring and cutting of material.

High quality

The Green Wall system allows you to work in an exact and millimetric way, making a high-quality final product.

Anti-seismic

The properties of the Green Wall system, such as the lightness and flexibility of EPS, contribute to improve the seismic resistance of buildings, reducing the risk of structural damage compared to concrete and rock slab, which can be more rigid and susceptible to cracking in case of seismic movements. In fact, you will never see expansion joints

Cost savings

Energy savings

Less labor

The installation of the Green Wall system requires less labor compared to methods like concrete, which involve multiple stages of construction, such as forming, pouring and finishing. This can translate into lower labor costs and shorter construction times.

Customized

The Green Wall system allows for a wide variety of decorative and customized finishes, adapting to the aesthetic tastes and specific requirements of the client. This provides greater flexibility compared to concrete and sheet rock, which may have limited finishing options and require additional processes to achieve the same Acoustic level of customization.

Acoustic

The Green Wall system by its composition of materials is a natural sound absorber, allowing an ideal acoustic insulation. If we add ways to deflect sound waves to solve acoustic is integral.

Recyclable

Some of the finishes within your reach

The Green Wall system allows for a wide variety of decorative and customized finishes, adapting to the aesthetic tastes and specific requirements of the client.

Green Wall Coral Coat™

Green Wall Light Sand™

Green Wall Precast™

Green Wall Rustic Coral™

Green Wall Sand Coat™

Green Wall Smooth™

Green Wall Hard Sand™

Green Wall Wood Grain™

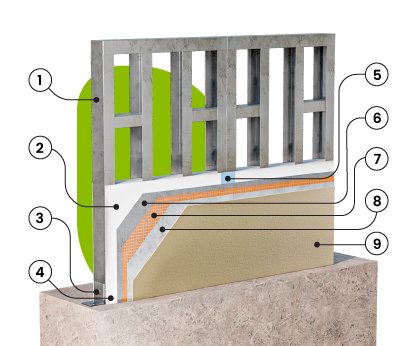

Composition of

Green Wall Panel System

Description

1) Metal studs and tracks, Cal. 18 and 20

2) High-density EPS, from R13 to R32

Technically it is defined as:

“Cellular and rigid plastic material manufactured from the molding of pre-expanded beads of expandable polystyrene or one of its copolymers, which has a closed cellular structure filled with air”

3) Metal square and expander anchor with epoxy

.